Time:[2019-05-24]

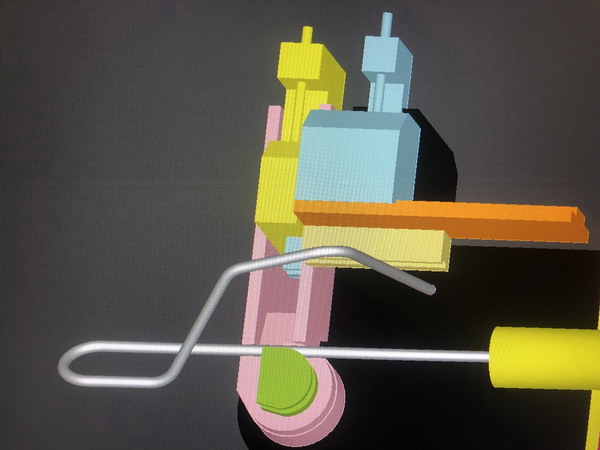

The team of Zhejiang King-Mazon Machinery Co., Ltd. has been paying close attention to the development of China's aerospace industry since 2003, and has been engaged in the research on the manufacturing technology of precision tube in aerospace vehicles, including stainless steel tube, titanium alloytube, nickel-based alloy tube and so on.It has successfully researched the digital bending technology of various specifications of metal pipe, which can develop the knowledge of pipe bending forming into database technology, and closely combine it with the manufacturing process of CNC pipe bender to realize various kinds of high-precision and high-reliability tube for aerospace vehicles.Thorough study of the special report of Hainan daily on March 11, 2019 shows the spirit of exploring the moon to build China into a space power.The Geomagic Studio is reverse engineering for Geomagic's products. It can automatically generate an accurate digital model based on any physical part by scanning the spot cloud.Geomagic Studio also offers the ideal option for some emerging applications, such as mass production of custom equipment, a made-to-order production model, and automated remanufacturing of raw parts.Geomagic Studio can be the perfect complement to CAD, CAE, and CAM tools for exporting industry-standard formats, including many file formats such as STL, IGES, STEP, and CAD.

1. Automatically convert point cloud data into Polygons;

2. Decimate polygons quickly;

3. Transform polygons into NURBS surfaces;

4. Surface analysis (tolerance analysis, etc.);

5. Output file formats matching CAD/CAM/CAE (IGS, STL, DXF, etc.);

Edit main advantages: ensure users get perfect polygons;When dealing with complex shapes or free surface shapes, the productivity is more efficient than traditional CAD software.Automation features and simplified workflows reduce training time and save users from tedious, labor-intensive tasks;Can be integrated with all major 3d scanning equipment and CAD/CAM software;Can be used as a stand-alone application for rapid manufacturing or as a complement to CAD software.King-Mazon team can make full use of scientific means to realize digital manufacturing of metal tube manufacturing without adjusting tooling, and push metal tube manufacturing technology to a new height.The latest technology can be loaded on your computer and can be loaded on your computer instantly.

Contact the academy at 0086-578-3182282,0086-13905781127 and email at king@king-mazon.com.

Hotline

Copyright ©Zhejiang King-Mazon Intelligent Manufacturing Corp., Ltd. 浙ICP 备05037799号