EQUIPMENT PRODUCTS

General Introduction

Wisdom CNC Pipe Bender is the advanced Pipe Bender with multi-axis servo motor controlling and multi-layer mould function. Desighed by GBEMA, a historical Italia Pipe Bender company, this machine applys professional skills of industrial computer and CNC Pipe Bender into multi-axis servo motor and hydraulic servo driving. It can work automaically like feeding,rotating,changing moulds, reading drawings, editing andrevising technical documents and correcting datas.What’s more, working with robots, it also can loading and unloading automaitcally, testing pipes and revise technical datas and production procedures according to the test result.It can diagnose fault automaically, 3D pipe display and simulation,3D interference detection,etc.It is the first choice for the field of aerospace,nuclear power, automobile, motorcycle, shipbuilding, petrochemical,electricity, gas, boilers, fitness and sports equipment to bending pipes. 1-9stack tooling is optional.

Feature Highlights

1. Multi-axisservo drive and IPC system equipment with high intelligence and automation. Itcan be processed by stretch bending or stretch bending plus pushing bending.

2. Singleradius 3D bending with one pipe can be realized.

3.The manual, semi-auto and automatic operation can be set.

4. Thebending data can be input directly to coordinate (X、Y、Z) or workingdata(Y、B、C). It is possibleto transfer between coordinate and working data, also can calculate the feedinglength precisely.

5.There will be a 3D graphic model after input the bending data, and the bendingprocess can be simulated for seeing the virtual picture

6. Theprogram image self editing.

7. When editing the bending programs, some bends can be add or deletefreely, and the editing programs can be memorized as a renamed program.

8.The storage of Max. bending programs and data are unlimited.

9. Duringexam bending, choosing the micro-motion to observe the interfere point, thenadjusting the moves to increasing the efficiency.

10. IPC control with 3D interference simulator.

11. Thefeeding style include clamp feeding and direct feeding

12. Thefeeding, bending and rotating axes all have multiple speed choices, for thesame pipe, each bend can set the speed individually.

13. Thefunction of mandrel auto oiling lubrication can be start or cancel by software.

14. The perfect machine defaults alarming functions. The alarm message will beshowed on screen. It is easy for searching and clearing faults.

15. Multiplepersonal security protection is available.

16. 3D data reading and 3D digital measurement reverse compensation function

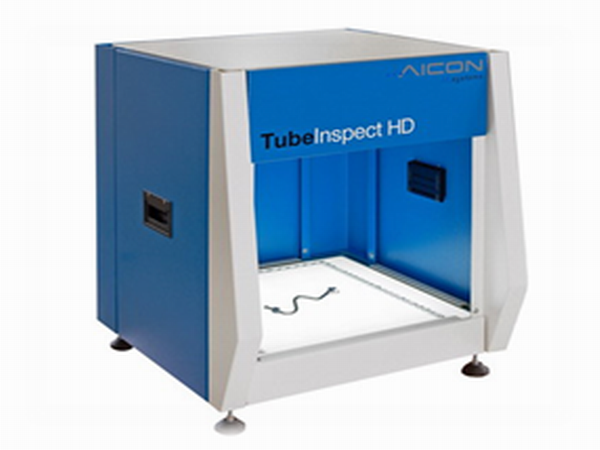

King Mazon CNC pipe bender can read 3D digital model (such as.* CATPart,.*STP) and automatically convert them into working parameters of the equipment. It has the function of calculating and compensating the bending springback database and the reverse compensation according to the actual value measured by the measuring instrument. Available for real-time communication with measuring equipment such as TubeInspect and articular arm measuring instrument, and compatible with actual bending data of catheter. It has the function of online measurement and automatic reverse correction of pipe bending process parameters. It is equipped with the interface to realize communication with the robot, so as to set up the production line with automatic feeding and unloading function of the robot.

Hotline

Copyright ©Zhejiang King-Mazon Intelligent Manufacturing Corp., Ltd. 浙ICP 备05037799号