EQUIPMENT PRODUCTS

General Introduction

Intelligence style CNC pipe bender adoptsIPC numerical control system and professional software of pipe bender, drivingby servo-motor and hydraulic pressure. Providing the automatic functions offeeding, rotating, die exchanging, drawings reading, editing, file modifying,rebound data adjusting, automatic faults diagnosing and 3D display. The Max.capability of this machine is OD 450mm, after equipped the power push bendingfunction, the Min. bending radius can achieve R≤1D. This machine is adequatefor high precision and complex 3D cold bending of each thick wall or thin wallsteel pipe, also the alloy metal .The moves are controlled by the advanced IPCsystem, increasing the processing quality and producing efficiency. Thismachine has the advantages of high automation, high precision, high precision,high working efficiency and low labor intensity, It is the most ideal equipmentfor aerospace, automobile, locomotive, motorcycle, shipyard, petrochemical,electric power, natural gas, nuclear industry, boiler, vehicles, fitnessequipment and sports equipment. The range of the multi stacks is from 1 layerto 3 layers.

Feature Highlights

1. 5-10 axis servo control.

2. Multi-stack, right or left bending.

3. Multi-radius bending, 3D bendingdirection

4. Push bending feature, big radius bending

5. Direct power push and side power pushbending.

6. IPC control with 3D interferencesimulator.

7. Connecting to measuring device optional.

8. Automatic mandrel lubrication.

9. Hydraulic oil cooling system.

10. On-line technical support service.

11. Total product solution working cell.

12. 3D data reading and 3D digital measurement reverse compensation function.

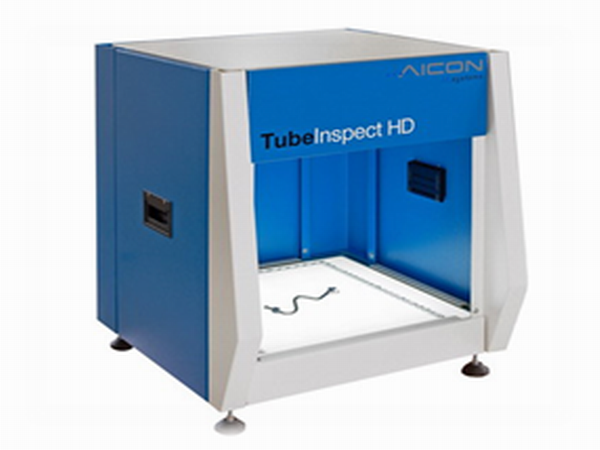

King Mazon CNC pipe bender can read 3D digital model (such as.* CATPart,.*STP) and automatically convert them into working parameters of the equipment. It has the function of calculating and compensating the bending springback database and the reverse compensation according to the actual value measured by the measuring instrument. Available for real-time communication with measuring equipment such as TubeInspect and articular arm measuring instrument, and compatible with actual bending data of catheter. It has the function of online measurement and automatic reverse correction of pipe bending process parameters. It is equipped with the interface to realize communication with the robot, so as to set up the production line with automatic feeding and unloading function of the robot.

Hotline

Copyright ©Zhejiang King-Mazon Intelligent Manufacturing Corp., Ltd. 浙ICP 备05037799号