EQUIPMENT PRODUCTS

1.Profile Introduction

This product is GBEMA brand original drawing technology product introduced from Italy by King-Mazon. It is driven by servo motor, and the machine does not need hydraulic system.The metal plastic forming mechanism is mainly applied to the forming of the tube/pipe fitting end.Such as flaring, reducing, bead, turn over, punching processing.CNC pipe end molding machine is mainly used in aircraft, rockets, engine, auto parts, heat exchange equipment, medical equipment and other pipe end forming. This CNC End Forming machine mainly applied in area of air plane, rockets, engine, auto,heat exhcanger,medical equipment. Design with 6 stack tooling station(optional 8 or 10 stations), one stack or multi stack tooling is for rotating function, CNC tube end forming machine through servo motor for tooling change and rotary head feed and drive, after the pipe fitting installed on the machine, CNC tube end molding machine is fully automatic on the end of the pipe fitting for five times expansion shrinkage and a spinning processing. Numerical control tube end forming machine structure design is reasonable, has enough dynamic, static stiffness. The main parts of the CNC tube end molding machine are made of high-quality materials. The mechanical, electrical, pneumatic, hydraulic components and control system are advanced, high-quality and reliable series of products. CNC tube end forming machine has high automation, simple operation, beautiful shape, high efficiency, high reliability and high precision.

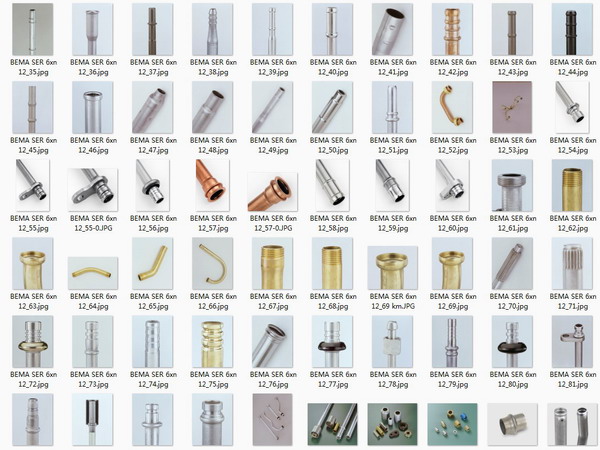

2.Main Application

The end forming machine is mainly applied to the forming of the tube/pipe fitting end. Such as flaring, reducing, bead, turn over, punching processing.

3.Reference Picture

Feature Highlights

Horizontal design;

Machine design with 1 to 6 stations,one is rotating station.

Tooling die is installed on the machine head, which moves horizontally and is driven by oil cylinder.

Design with horizontal direction clamping method.

The method for the forming processis clamp the tube/pipe fitting make it still and moving the tooling.

Can have at the same time expand, reducing, groove, sleeve assembly, sleeve upsetting and other function.

Feed motion driven by Siemens servo motor, high precision.

Siemens CNC system is adopted to control the automatic operation of the equipment.

The multi-station tube end-forming machine has an independent lubrication system for processing products.

Multi-station tube end shaper has compressed air chip blowing device.

The multi-station tube end forming machine has the function of locating the front and back end of the tube to ensure that it meetins the requirements after forming.

Equipped with hydraulic cooling system to ensure long time stable operation of the machine..

Has manufal, automatic function , and with an emergency stop device, high security.

In the manual mode, it has the function of touch control, which is easy to adjust the machine and tooling.

The processing time of each station is 3-6 seconds/piece.

In the automatic mode, after starting the foot switch , the machine automatically completes a workpiece processing, improve efficiency.

The machine is designed with counter function, which can record the processing quantity of the shift.

Hotline

Copyright ©Zhejiang King-Mazon Intelligent Manufacturing Corp., Ltd. 浙ICP 备05037799号