EQUIPMENT PRODUCTS

General Introduction

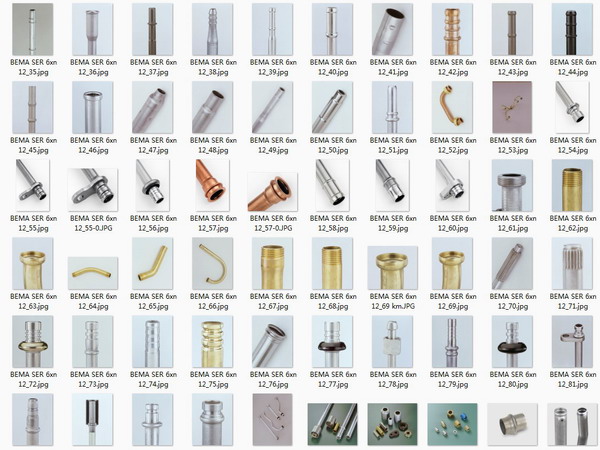

This product is GBEMA brand original drawing technology product in troduced from Italy by King-Mazon. Multi-station tube end machine is have a combination of multiple tooling location of pipe end forming machine, with horizontal design, can choose 1 to 10 tooling station, uses cylinder to clamp the workpiece, hydraulic cylinder pushing forming tooling, through the extrusion tooling for pipe end forming, can have a combination of expansion and reducing,spinning etc. Usually used in aircraft tube, auto parts, air conditioning fittings, hardware products and other industries.

Feature Highlights:

1. Multi-Station End Forming Machineis horizontal design.

2. Tooling installed on the machine head, head moves in horizontal anddriven by hyaraulic cylinder.

2. Head of Multi-Station End Forming Machine equipped with 1-10 sationforming machine(optional)

3. Two clamping ways as horizontal clamping and vertical clamping bydifferent forming force.

4. Rotating device is optional, rotation can be clockwise andanticlockwise.

5. Pipe is clamping and fixing, but toling is moving for forming pipe.

6. Multi-Station End Forming Machine can expand,reduce or form othershape pipe.

7. Servo control the different kinds of rotating.

8. Multi-Station End Forming Machine has independent rotation and timinglubrication system.

9. Multi-Station End Forming Machine has lubrication system forproduct,each station equipped with lubrication.

10. Multi-Station End Forming Machine has compressed air huff nails.(optional)

11. Multi-Station End Forming Machine has function of automaticpositioning.

12. Hydraulic cooling system to insure long time stable work.

13. Manual,Auto-running mode, with emergency button.

Hotline

Copyright ©Zhejiang King-Mazon Intelligent Manufacturing Corp., Ltd. 浙ICP 备05037799号